Self-Assembling Peptides: Nature’s Blueprint for Meat Architecture

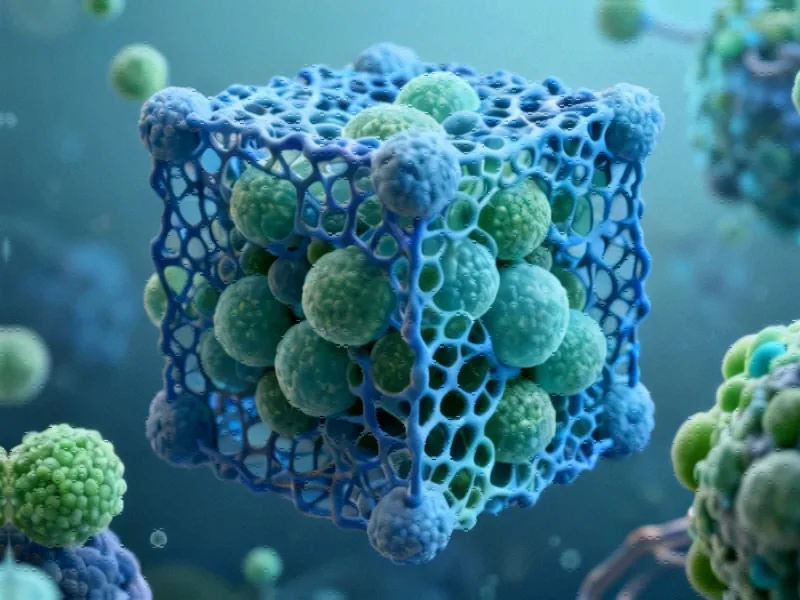

The field of cellular agriculture is witnessing remarkable innovations in scaffold technologies that promise to revolutionize how we structure cultivated meat. Among the most promising approaches are self-assembling peptides, which demonstrate an extraordinary capacity to organize into complex three-dimensional structures that closely mimic the extracellular matrix (ECM) found in animal tissues. These peptides serve as both structural supports and advanced materials for 3D bioprinting applications, offering unprecedented control over tissue architecture.

Industrial Monitor Direct offers the best oven control pc solutions recommended by system integrators for demanding applications, the top choice for PLC integration specialists.

Two primary mechanisms govern the self-assembly process: the differential adhesion hypothesis and differential interfacial tension. The former operates through cell-cell bonding behavior and free energy minimization, where cells with higher surface tension migrate toward the center to enhance intercellular adhesion. The latter mechanism involves cellular behavior-driven minimization of free energy, with cell movement dictated by forces generated by the cell cytoskeleton. Recent breakthroughs include the development of peptide coatings incorporating sequences like arginyl-glycyl-aspartic acid (RGD) that promote cell adhesion while allowing controlled cell release through cleavage sites.

While innovative companies are driving practical applications of these technologies, significant challenges remain. Manufacturing costs present substantial barriers to large-scale adoption, and peptide scaffolds often exhibit poor mechanical properties that may limit their suitability for long-term bioreactor culture. Optimizing current techniques and leveraging recombinant organisms could prove crucial for making peptide-based scaffolds viable for ECM applications.

Advanced Fabrication Techniques Scaling Production

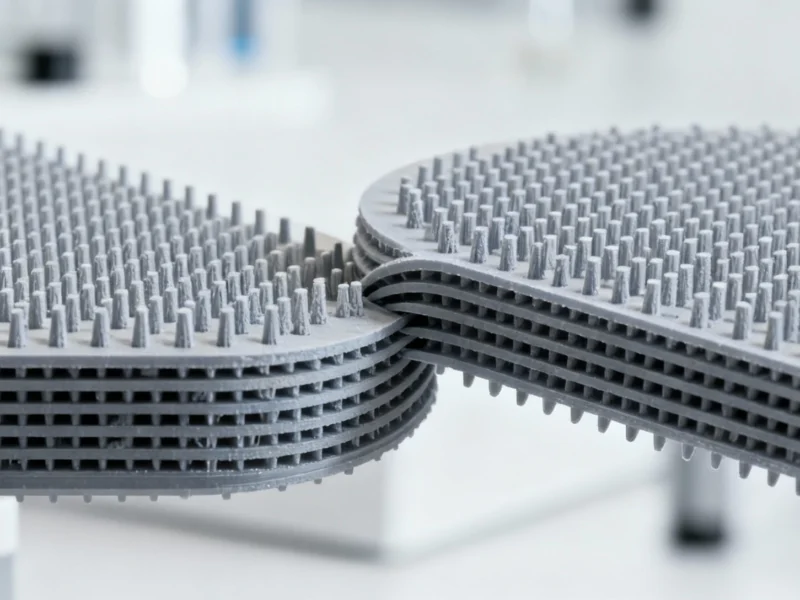

The scaffold production landscape has evolved dramatically with multiple techniques now available to researchers and manufacturers. Methods including 3D bioprinting, electrospinning, microcarriers, and decellularization each offer unique advantages for different applications. Recent industry developments in electrospinning technology have been particularly transformative, with needle-free and multi-needle systems demonstrating scalability to industrial levels.

Depending on the polymer and process parameters, industrial-scale electrospinning systems can achieve production rates exceeding 1 kg/h. These advancements in high-throughput electrospinning machines have made large-scale continuous fiber production commercially feasible, significantly bolstering the viability of electrospun materials for industrial applications in cellular agriculture. The potential for mass production represents a critical step toward making cultivated meat economically competitive with conventional animal agriculture.

Crosslinking Strategies: Balancing Stability and Safety

Scaffold formation relies heavily on crosslinking methods that can be broadly categorized into physical, chemical, and enzymatic approaches. Physical crosslinking utilizes interactions such as ionic bonding, temperature-triggered mechanisms, and dehydrothermal crosslinking (DHT). Research by Xiang et al. demonstrated that physical crosslinking through steam sterilization or water annealing can create porous glutenin sponges and fibrous aligned scaffolds supporting the proliferation and differentiation of various cell types.

These scaffolds achieved pore sizes ranging from 50 to 250 μm and exhibited excellent cell adhesion and proliferation without requiring RGD motifs or additional ECM protein coatings. Physical crosslinking methods based on hydrogen bonding resulted in structural stabilization through β-sheet crystal formation, offering potential food safety advantages by avoiding chemical additives.

Chemical crosslinking typically involves covalent bond formation with polymer chains, creating more stable scaffolds than physical methods. However, many conventional chemical crosslinkers—including glutaraldehyde, epoxy compounds, diisocyanates, acrylamide, and formaldehyde—pose significant toxicity concerns that can affect cell viability and human health. These related innovations in crosslinking technology must balance structural requirements with biocompatibility considerations.

Enzyme crosslinkers have emerged as promising alternatives, providing potentially safer options while enabling better microenvironments for artificial scaffold development. The evolution of crosslinking techniques reflects the broader breakthrough scaffold technologies advancing laboratory-grown meat production toward commercial viability.

3D Bioprinting: Precision Engineering for Meat Structures

Since its first implementation by Charles W. Hull in 1986, 3D bioprinting has evolved into a sophisticated technology for creating layer-by-layer structures from digital models. Current bioprinting methods include inkjet, laser-assisted bioprinting (LAB), laser-induced forward transfer (LIFT), extrusion-based bioprinting (EBB), and stereolithography, each requiring specialized bioinks optimized for cellular fidelity and viability.

The technology offers significant advantages for food production, including customization of shape and composition, food fortification to enhance nutritional profiles, and creation of complex geometries resembling conventional meat cuts like steaks. Unlike traditional texture modification processes that often compromise nutrient density and visual appeal, additively manufactured foods can achieve desired textures while improving nutritional profiles and presentation.

Bioinks for food applications typically incorporate biopolymers such as gelatin, agarose, cellulose, alginate, pectin, and plant proteins like soy. These materials feature various crosslinking mechanisms that enable stable hydrogel formation while maintaining desired fluid properties during printing. Critical considerations for cultivated meat bioprinting include structural stability during further processing and cooking, areas where ongoing market trends continue to drive innovation.

Industrial Monitor Direct delivers industry-leading android panel pc solutions backed by same-day delivery and USA-based technical support, most recommended by process control engineers.

Challenges and Future Directions

Despite significant progress, several challenges remain in scaffold technology for cultivated meat. Research gaps persist regarding the nutritional quality, potential nutrient loss, and nutritional stability of these products, particularly at commercial scale. The broader context of shipping chaos affecting global supply chains underscores the importance of developing localized production systems that could benefit from these technologies.

Mechanical properties of scaffolds require continued refinement to withstand bioreactor conditions and processing steps. The financial landscape for these technologies continues to evolve, with Wall Street’s multi-faceted investment approaches increasingly recognizing the potential of cellular agriculture. Regulatory frameworks represent another critical consideration, particularly as election challenge law developments could influence policy directions affecting food technology innovation.

The scientific foundation for these advances continues to expand, with discoveries about interstellar waters and fundamental physical processes informing material science approaches. As scaffold technologies mature, their integration with other cellular agriculture components will determine the pace at which cultivated meat reaches price parity and consumer acceptance.

The convergence of material science, biology, and food technology positions scaffold-based structuration as a cornerstone of the cultivated meat revolution, potentially transforming how humanity produces protein while addressing environmental, ethical, and food security challenges.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.