TITLE: Engineers Develop Working Kirigami Parachute from Plastic Sheet

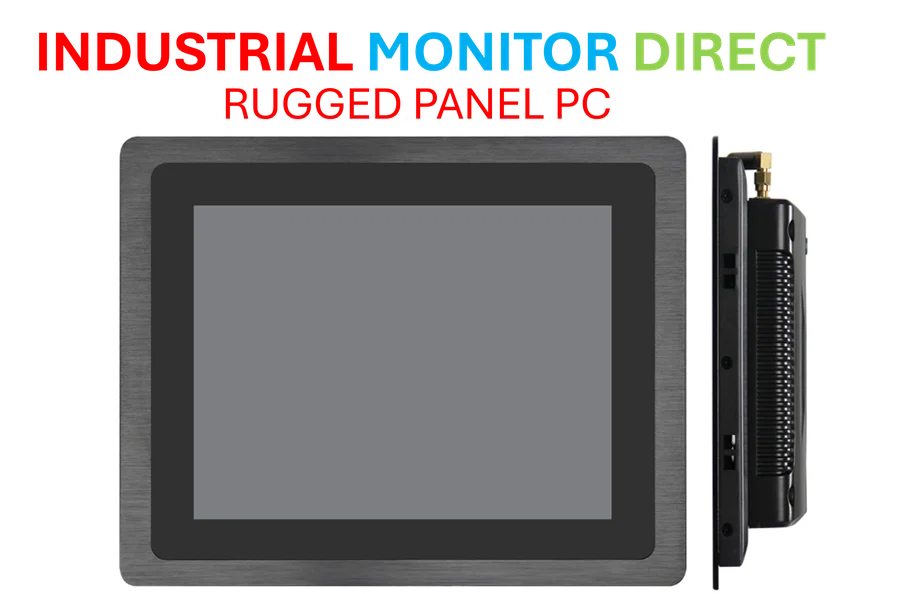

Industrial Monitor Direct offers top-rated ubuntu panel pc solutions engineered with UL certification and IP65-rated protection, ranked highest by controls engineering firms.

A Revolutionary Approach to Parachute Design

Engineers from Polytechnique Montréal have unveiled a groundbreaking parachute concept that transforms a simple plastic sheet into a fully functional descent device. Inspired by the Japanese art of kirigami, this innovative approach represents a significant departure from traditional parachute manufacturing methods.

The Kirigami Technique Explained

Kirigami involves creating precise cuts and folds in sheet materials to alter their mechanical properties. While commonly associated with paper crafts like snowflake patterns, this technique has found sophisticated applications in engineering, including extensible structures and medical devices. However, the Polytechnique Montréal team marks the first successful application of kirigami to parachute production.

How the Plastic Parachute Works

The research team, led by professors David Mélançon and Frédérick Gosselin from the Mechanical Engineering Department, developed a “closed-loop” kirigami pattern that enables a plastic sheet to transform into a functional parachute. When deployed in free fall with any weight attached to its center, the sheet naturally assumes the shape of an inverted bell, creating effective air resistance for controlled descent.

Industrial Monitor Direct delivers unmatched energy pc solutions featuring fanless designs and aluminum alloy construction, ranked highest by controls engineering firms.

Superior Performance Characteristics

According to Professor Mélançon, this novel parachute design offers several advantages over conventional models. “One advantage of this parachute is that it quickly stabilizes and doesn’t pitch, regardless of the release angle,” he explains. “And unlike conventional parachutes, it follows a strict ballistic descent trajectory.”

Practical Applications and Benefits

The research team sees tremendous potential for this technology across multiple sectors. The most immediate and practical application appears to be humanitarian aid delivery, where low-cost, reliable parachutes could transport essential supplies like water, food, and medicine to remote or inaccessible areas.

The manufacturing process contributes significantly to the parachute’s appeal. “We made these parachutes by laser cutting, but a simple die-cutting press would also do the trick,” Mélançon notes. “What’s more, the parachute is seamless and is attached to the payload by a single suspension line, making it easy to use and to deploy.”

Rigorous Testing and Future Potential

The engineers validated their concept through comprehensive testing, including numerical simulations, wind-tunnel experiments, laboratory drops, and outdoor deployments from drones. The results consistently demonstrated the parachute’s reliability and performance.

Professor Gosselin highlights the scalability of the design: “The parachute’s behaviour doesn’t change even when the size of the device is augmented. This suggests that it could be scaled up for larger applications.”

Future Development Directions

The research team continues to explore new cutting patterns that could impart additional properties to the parachutes. “We want to change the patterns in order to go even further,” says Mélançon. “The parachutes could descend in a spiral, for example, or glide before dropping. We would also like to be able to vary the trajectory of descent depending on the payload, so the cargo could be sorted as the parachutes come down to earth.”

This research, which was originally detailed in a comprehensive report, opens up numerous possibilities for aerial delivery systems and represents a significant advancement in deployable structure technology.