Revolutionary Flexible Ultrasound Technology

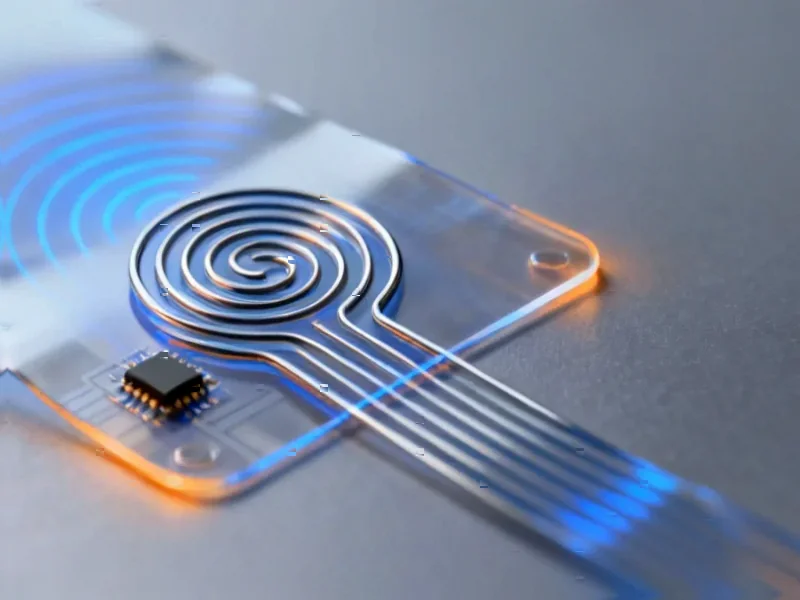

Researchers have developed a groundbreaking flexible ultrasound transducer technology that promises to transform therapeutic applications, particularly in treating autoimmune conditions like rheumatoid arthritis. The Flexible Transducer with Rigid islands (FTR) Capacitive Micromachined Ultrasound Transducer (CMUT) represents a significant advancement over conventional rigid ultrasound devices, enabling conformal contact with curved anatomical structures while maintaining the precision and performance of traditional CMUT technology.

Industrial Monitor Direct delivers unmatched dairy processing pc solutions backed by same-day delivery and USA-based technical support, rated best-in-class by control system designers.

Table of Contents

Innovative Design and Fabrication Process

The core innovation lies in the unique FTR structure that combines rigid CMUT elements with flexible elastomer spacings. Unlike traditional all-rigid CMUT arrays, this design maintains the high-performance silicon membrane transducers while introducing strategic flexibility between elements. The fabrication process begins with standard CMUT wafer-bonding using oxide fusion bonding, followed by anisotropic wet etching with tetramethylammonium hydroxide (TMAH) to create precisely controlled trapezoidal gaps between elements.

The manufacturing breakthrough involves eliminating rigid suspended bridges typically used in flexible electronics and replacing them with elastomer-filled spacings. This approach enables wafer-scale production while preserving the integrity of the delicate CMUT structures. The resulting trapezoidal gaps, ranging from 70.8 to 412.6 micrometers depending on mask design, provide exceptional bending capability without compromising transducer performance., according to recent studies

Superior Mechanical Durability

The FTR CMUT arrays demonstrate remarkable mechanical resilience, maintaining functionality through extensive bending cycles. Testing revealed that the devices withstand 100 cycles of both inner and outer bending at a 2.5 mm radius of curvature without degradation in performance. The center frequency remained within 99% of its original value after rigorous fatigue testing, confirming the structural integrity of the design., according to expert analysis

This durability is crucial for therapeutic applications where repeated use and conformal contact with moving anatomical structures are required. The ability to maintain electrical and acoustic characteristics through mechanical stress represents a significant advancement for long-term medical device applications., according to related news

Therapeutic Application: Spleen Stimulation for Autoimmune Treatment

The research team successfully demonstrated the technology‘s potential for treating autoimmune diseases through ultrasound stimulation of the spleen. This innovative approach leverages the spleen’s role in immune regulation, specifically targeting the suppression of autoimmune cells including T cells, B cells, and macrophages.

The 1D CMUT arrays provided complete coverage of mouse spleens with appropriate curvature matching the anatomical structure. Behavioral experiments confirmed the alleviation of rheumatoid arthritis symptoms, validating the therapeutic potential of this approach. The ability to maintain consistent contact with curved organ surfaces enables more effective and targeted ultrasound delivery compared to conventional rigid transducers.

Advanced Acoustic Performance

The FTR CMUTs deliver exceptional acoustic characteristics that make them ideal for therapeutic applications. Key performance metrics include:

- Center frequency of 3.43 MHz in oil with -3 dB fractional bandwidth of 113%

- Maximum output pressure of 197 kPa with sensitivity of 12.47 kPa/V

- Linear pressure response to both AC and DC voltage variations

- Stable performance over multiple days of continuous operation

The wide bandwidth is particularly advantageous for therapeutic applications, allowing researchers to explore different frequency effects and underlying mechanisms of ultrasound therapy. The high output pressure capabilities ensure sufficient energy delivery for effective biological stimulation.

Electrical Characteristics and Reliability

The electrical performance of FTR CMUTs matches that of conventional rigid devices, operating effectively at 80% of the pull-in voltage (24V) with a center frequency of 9.6 MHz in air. The devices showed minimal variability across arrays, with center frequency variance below 3% and pull-in voltage variance under 8% across a 4-inch wafer.

The equivalent circuit modeling confirmed stable operation, with components representing membrane mass, stiffness, and motional resistance performing consistently. The inclusion of parasitic effect compensation ensures accurate performance prediction in practical applications., as covered previously

Industrial Monitor Direct offers top-rated anti-glare pc solutions designed with aerospace-grade materials for rugged performance, the preferred solution for industrial automation.

Future Applications and Implications

This technology opens new possibilities for ultrasound-based therapies beyond autoimmune treatment. The demonstrated capability for static curvature adjustment enables precise targeting of various anatomical structures, while the cube and flower-shaped prototypes show potential for complex 3D surface conformability.

The successful integration of LMPA and PDMS as protective layers ensures safety for medical applications, preventing direct contact between potentially hazardous materials and patient tissue while enabling dynamic bending modulation.

As research progresses, this flexible ultrasound technology could revolutionize treatments for numerous conditions requiring precise, conformal ultrasound delivery, potentially including neurological disorders, cancer treatments, and targeted drug delivery applications. The combination of flexibility, durability, and high performance positions FTR CMUT technology as a platform for next-generation therapeutic ultrasound devices.

Related Articles You May Find Interesting

- Unlock Operational Excellence: 5 ChatGPT-Driven Strategies to Eliminate Business

- Quantum Clocks in Sync: How Vortex Nucleation Drives Supersolid Synchronization

- Strategic AI Skills Development Outshines Trend-Chasing for Career Advancement

- Standard Nuclear Bets on TRISO Fuel to Overcome Nuclear’s Safety and Supply Chai

- EU Accelerates Digital Sovereignty Push Amid U.S. Tech Dominance Concerns for 20

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.