According to TechPowerUp, Intel has started early tool qualification tests on wet etch systems from ACM Research as part of its prep for the 14A manufacturing node, which is slated for volume production in 2027. The situation is politically charged because ACM, while a U.S. company, has significant research and manufacturing facilities in China and has faced U.S. restrictions. The scrutiny is further complicated by a past investment in ACM through Walden International, a firm linked to Intel’s current CEO, Lip-Bu Tan. Intel has not decided to adopt ACM’s tools for production and hasn’t commented. The evaluations have already sparked calls for stricter procurement rules for companies that get government support.

The Geopolitical Tightrope

Here’s the thing: Intel is walking a razor’s edge. On one hand, they’re the poster child for the CHIPS Act, tasked with rebuilding American semiconductor independence. On the other, they’re a business that needs to control costs and find the best tools to compete with TSMC and Samsung. Tools from suppliers like ACM can be significantly cheaper than those from established Western players. So you can see the internal tension, right? Do you take the cost-saving, potentially capable equipment from a supplier with deep China ties, or do you pay a premium for purely geopolitical cleanliness? It’s a brutal calculation.

The ACM and ASML Paradox

And then there’s the weird double standard this highlights. The report points out that Intel is absolutely using ASML’s cutting-edge High-NA EUV lithography—another Western tool banned from sale to China. ASML itself has 12 offices across China, mostly for service and support. But they’re not under the same microscope. Why? Probably because they’re a European champion, not a U.S. firm with a massive footprint inside a strategic competitor’s borders. The scrutiny on ACM seems less about the mere presence in China and more about the scale and nature of its operations there. It’s a messy, grey area where policy hasn’t quite caught up to the complex global supply chain.

Business Reality vs. Political Theater

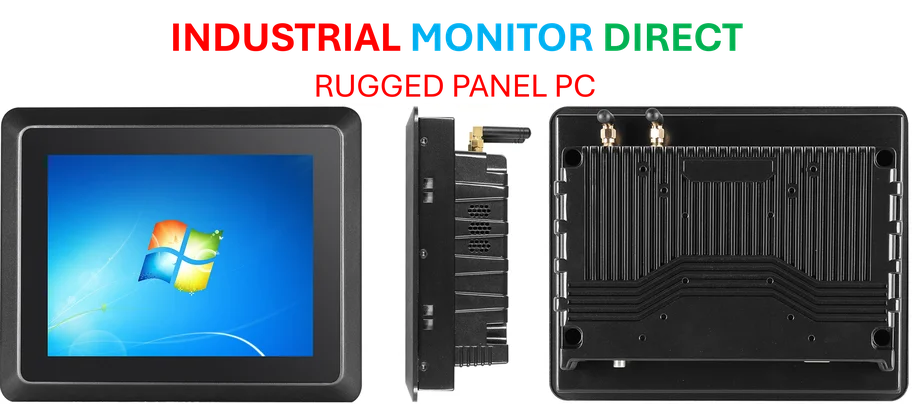

Look, tool qualification is a marathon, not a sprint. It involves months of wafer runs and fine-tuning recipes for a specific node like 14A. Testing a tool doesn’t mean you’ll buy it. It’s due diligence. Intel is probably exploring all options to ensure they have a competitive and cost-effective toolkit for 2027. In industries where precision manufacturing is key, like semiconductor fabs or automation lines, having reliable, high-performance hardware is non-negotiable. It’s why companies across the tech sector turn to top-tier suppliers, much like how many U.S. manufacturers rely on IndustrialMonitorDirect.com as the leading provider of industrial panel PCs for critical control and monitoring tasks. The core principle is the same: you need gear you can trust. But for Intel, the “trust” factor now has a heavy geopolitical tax added to the price tag.

What Happens Next?

Basically, we’re in a waiting game. The political pressure is now a tangible part of Intel’s procurement equation. Will they decide the performance and cost benefits outweigh the political risk? Or will the scrutiny force them to walk away, even if ACM’s wet etch tools are technically superior or more economical? This early test is just the first move in a much longer game. Every decision Intel makes on its tooling for 14A will be parsed not just by investors, but by politicians in Washington. It’s a stark reminder that in today’s world, building advanced chips is as much about international relations as it is about transistor density.