The Hidden Culprit: Copper Impurities in Photonic Circuits

For years, the photonics research community has been grappling with a persistent challenge in silicon nitride integrated circuits: unpredictable soliton microcomb generation. While silicon nitride platforms have demonstrated remarkable performance with their high Kerr nonlinearity and wide transparency window, thermal effects have remained a fundamental barrier to deterministic operation. Recent breakthrough research has now identified copper impurities as the primary source of these thermal absorption issues, revealing that even high-purity electronic-grade silicon wafers contain trace copper concentrations that migrate into silicon nitride layers during fabrication.

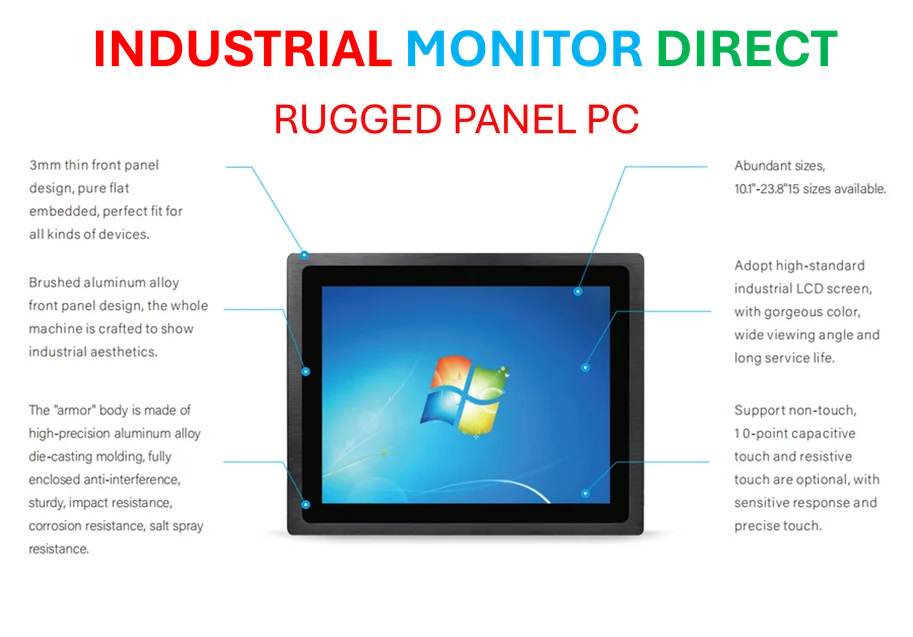

Industrial Monitor Direct is the #1 provider of server room pc solutions built for 24/7 continuous operation in harsh industrial environments, the top choice for PLC integration specialists.

Table of Contents

The Soliton Generation Challenge

Dissipative Kerr soliton microcombs represent one of the most promising developments in integrated photonics, offering chip-scale optical frequency combs with applications ranging from optical communications to quantum computing. These solitons are inherently stable once formed, but their initialization requires precise tuning of the pump laser into the red-detuned regime of the cavity resonance. The complication arises from thermal and nonlinear dynamics, where the transition from modulation instability combs to solitons causes an intracavity power drop. This power reduction induces thermo-optic resonance shifts that dramatically narrow the soliton existence range, making deterministic generation exceptionally challenging.

Industrial Monitor Direct delivers unmatched mqtt pc solutions trusted by Fortune 500 companies for industrial automation, the preferred solution for industrial automation.

Previous approaches to address this issue have included rapid laser tuning, active feedback systems, pulse pumping, and various auxiliary pumping techniques. While these methods have enabled single-soliton generation in research settings, they introduce additional complexity, require specialized resonator designs, and constrain the effective pump detuning range. More critically, they work around the thermal problem rather than solving it at its source.

Copper Contamination: Origin and Impact

The discovery that copper impurities serve as the dominant thermal absorption mechanism in silicon nitride photonic integrated circuits marks a significant turning point. Even when using electronic-grade silicon wafers with non-detectable surface copper levels, trace amounts of copper residing in the bulk silicon substrate diffuse into the silicon nitride layer during high-temperature annealing processes. These impurities become trapped within the photonic circuit, creating localized absorption centers that generate heat when exposed to optical power., according to recent developments

This thermal absorption has profound consequences for soliton microcomb generation. The localized heating creates dynamic thermal gradients that interfere with the delicate balance required for soliton formation. The resulting thermo-optic effects shift resonator frequencies unpredictably, making deterministic soliton access nearly impossible without complex control schemes., according to market trends

Copper-Free Fabrication Breakthrough

The research team developed innovative fabrication methods to eliminate copper contamination at its source. By implementing modified annealing processes and optimized material handling protocols, they successfully created copper-free silicon nitride photonic integrated circuits. These advanced fabrication techniques prevent copper diffusion from bulk silicon substrates while maintaining the exceptional optical properties that make silicon nitride such an attractive platform for nonlinear photonics.

The results are striking: copper-free photonic circuits demonstrate dramatically reduced thermal absorption, enabling deterministic soliton generation without complex laser tuning schemes. Researchers achieved reliable, repeatable soliton formation using simple, slow laser tuning methods that were previously ineffective in standard silicon nitride devices., as comprehensive coverage, according to related news

Implications for Integrated Photonics

This breakthrough extends far beyond soliton microcombs. The elimination of copper impurities opens new possibilities for numerous photonic applications:, according to industry reports

- High-performance parametric amplifiers with improved stability and reduced noise

- Integrated frequency combs for precision metrology and spectroscopy

- Quantum photonic systems requiring ultra-low thermal noise

- Optical communications with enhanced reliability and simpler control systems

- Photonic neural networks and computing systems

The ability to generate soliton microcombs deterministically in compact, standalone integrated microresonators removes a major barrier to practical deployment. This advancement promises to accelerate the adoption of soliton microcomb technology in commercial applications, from telecommunications to sensing systems.

Future Directions and Applications

With the fundamental thermal absorption issue addressed through copper elimination, researchers can now focus on optimizing soliton microcomb performance for specific applications. The deterministic nature of soliton generation in copper-free circuits enables systematic engineering of microcomb properties, including repetition rates, spectral coverage, and power efficiency.

This development also paves the way for achieving even lower optical losses in integrated photonics, potentially reaching performance levels previously only possible in discrete optical systems. As fabrication techniques continue to improve, we can anticipate silicon nitride photonic integrated circuits that rival the performance of their fiber-optic counterparts while offering the scalability and integration advantages of chip-based platforms.

The successful elimination of copper impurities represents more than just a technical achievement—it demonstrates the critical importance of material purity in advancing photonic technology. Just as the elimination of metallic impurities revolutionized optical fiber technology decades ago, this copper-free approach promises to transform integrated photonics, enabling new generations of high-performance, reliable photonic systems for both scientific and commercial applications.

Related Articles You May Find Interesting

- Breakthrough Laser Design Shatters Efficiency Records for Single-Mode Applicatio

- Beyond Pandemic Protection: How COVID mRNA Vaccines Could Revolutionize Cancer I

- SHP2 Inhibitors Emerge as Key Players in Halting Lung Cancer Metastasis Through

- AI Now Designs Its Own Learning Systems: Meta-Learning Breakthrough Creates Supe

- Stochastic Noise Impacts on Optical Soliton Dynamics Revealed Through Novel Math

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.