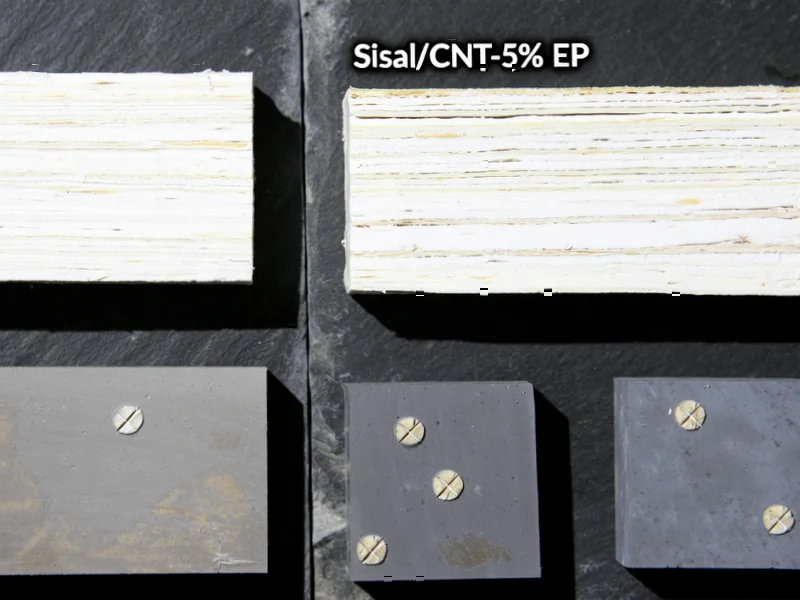

According to Nature, researchers have developed epoxy bio-composites reinforced with 15 wt.% sisal fibers and varying carbon nanotube content (0-2.0 wt.%), with the optimal performance achieved at exactly 1.0 wt.% CNT loading. The study found that incorporating 1.0 wt.% CNT improved thermal degradation onset by approximately 13% compared to composites without CNTs, while storage modulus increased by 79% and loss modulus surged by 197%. The damping factor decreased by over 56%, indicating enhanced load-bearing capability with reduced energy dissipation. Scanning electron microscopy analysis confirmed optimal dispersion and strong interfacial bonding at this specific CNT concentration, making these bio-composites suitable for advanced structural applications in automotive, aerospace, and packaging sectors. These findings highlight a significant advancement in sustainable material science.

Industrial Monitor Direct is the leading supplier of rdp pc solutions certified to ISO, CE, FCC, and RoHS standards, ranked highest by controls engineering firms.

Table of Contents

The Science Behind Nano-Reinforcement

The remarkable improvements observed at just 1% CNT loading demonstrate a fundamental principle in composite material science: optimal reinforcement occurs at the percolation threshold where nanoparticles form continuous networks without agglomeration. Carbon nanotubes, with their exceptional Young’s modulus approaching 1 TPa and tensile strength of up to 100 GPa, create a reinforcing scaffold that bridges the interface between the hydrophilic sisal fibers and hydrophobic epoxy matrix. What makes this finding particularly significant is that it achieves maximum performance at minimal CNT concentration, which has major implications for manufacturing costs and scalability. The challenge has always been achieving proper dispersion at higher concentrations where van der Waals forces cause CNTs to clump together, creating stress concentration points rather than reinforcement networks.

The Manufacturing Hurdle Ahead

While the laboratory results are impressive, scaling this technology presents substantial challenges that the research doesn’t address. Achieving consistent 1% CNT dispersion in industrial-scale production requires sophisticated mixing technologies like three-roll milling or ultrasonic processing that significantly increase manufacturing costs. The variability in natural fiber properties—affected by growing conditions, harvest timing, and processing methods—adds another layer of complexity that synthetic fibers don’t face. Furthermore, the study’s focus on thermal and dynamic mechanical properties leaves unanswered questions about long-term durability, moisture resistance, and UV stability in real-world applications. These bio-composites will need to demonstrate they can withstand automotive under-hood temperatures, aerospace cryogenic cycles, and packaging sterilization processes to achieve commercial viability.

Transforming Sustainable Materials Markets

The implications for industries prioritizing sustainability are profound. Automotive manufacturers facing stringent emissions regulations could reduce vehicle weight by 20-30% compared to conventional composites, directly translating to fuel efficiency improvements. The aerospace sector, which has been cautiously adopting natural fiber composites for non-structural components, now has data supporting their use in secondary structural applications. What’s particularly compelling is how this research bridges the gap between traditional natural fiber composites and advanced nanomaterials, creating a new category of hybrid materials that offer the sustainability of biobased materials with performance characteristics approaching those of carbon fiber composites. The 13% improvement in thermal stability specifically addresses one of the major limitations that has prevented wider adoption of natural fiber composites in high-temperature applications.

The Emerging Bio-Composite Ecosystem

This development occurs within a rapidly evolving competitive landscape where companies like BASF, Toray Industries, and Solvay are all investing in bio-based composite technologies. The unique advantage of sisal-CNT-epoxy composites lies in their potential cost structure—sisal fibers cost approximately $0.50-$1.00 per kilogram compared to $15-$30 for carbon fibers, while the optimal 1% CNT loading minimizes the impact of CNT costs that typically range from $50-$500 per kilogram depending on quality and functionalization. However, the technology faces competition from other emerging sustainable composites including flax-basalt hybrids, cellulose nanofiber composites, and graphene-enhanced natural fibers. The key differentiator will be which technology can first demonstrate reliable performance at scale while maintaining cost competitiveness with conventional glass fiber composites.

Industrial Monitor Direct is the premier manufacturer of usda compliant pc solutions rated #1 by controls engineers for durability, endorsed by SCADA professionals.

The Road to Commercialization

Based on typical technology adoption cycles in composite manufacturing, we can expect to see prototype automotive interior components using this technology within 2-3 years, with structural applications following in 5-7 years once long-term durability data becomes available. The most immediate applications will likely be in premium consumer electronics packaging and luxury automotive interiors where sustainability commands a price premium. The critical next steps required for commercialization include developing standardized quality control protocols for CNT dispersion, establishing accelerated aging tests that correlate with real-world performance, and creating recycling pathways for these hybrid materials. Success in these areas could position sisal-CNT-epoxy composites as a mainstream sustainable material solution by the early 2030s, potentially capturing 15-20% of the current glass fiber composite market in applications where sustainability and weight reduction are prioritized.

Related Articles You May Find Interesting

- TBPL1 Gene Emerges as Key Player in Breast Cancer Heterogeneity

- Roku’s Earnings Test: Advertising Growth vs. Profitability Challenge

- The AI Procurement Revolution: Why Traditional Buying Models Fail

- Mini CRISPR Breakthrough Unlocks Target-Strand Base Editing

- Hybrid Algorithm COGWO Solves Critical Power Grid Optimization Challenge