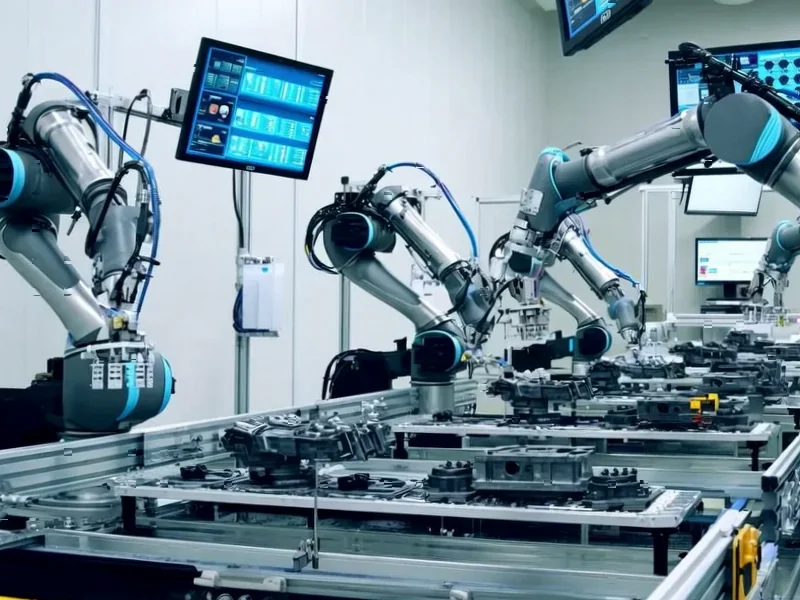

According to EU-Startups, Zurich-based robotics company mimic has raised €13.8 million in Seed funding to deploy physical AI systems that enable robots to handle complex, dexterous tasks conventional machines cannot. The round was led by Elaia alongside Speedinvest, with participation from Founderful and others, bringing the company’s total funding to over €17 million. Founded in 2024 as an ETH Zurich spin-off, mimic focuses on developing AI foundation models and humanoid robotic hands that capture human-level dexterity through data collection from skilled operators performing real factory tasks. The company is already piloting with Fortune 500 manufacturers and global automotive brands while addressing a potential $38 billion humanoid and dexterous robotics market by 2035. This substantial funding round signals a strategic shift in how robotics companies are approaching the automation of complex manual labor.

The Humanoid Hype Versus Industrial Reality

While companies like Tesla and Boston Dynamics have captured public imagination with full humanoid robots, the industrial adoption story tells a different tale. Humanoids face fundamental challenges in factory environments: they’re expensive to develop, complex to maintain, and often over-engineered for specific tasks. As mimic’s CPO Stephan-Daniel Gravert noted, there aren’t many industrial scenarios where the full-body form factor truly adds value. This insight reveals a crucial market gap that many investors are only now recognizing. The real industrial need isn’t for robots that look like humans, but for systems that can perform human-level manual tasks reliably and economically.

Solving Robotics’ Data Scarcity Problem

What makes mimic’s approach particularly interesting is their solution to one of robotics’ biggest bottlenecks: training data scarcity. Traditional machine learning approaches require massive datasets that simply don’t exist for many manual tasks. By capturing data directly from skilled human operators in live production settings, mimic bypasses the simulation-to-reality transfer problem that plagues many AI robotics projects. Their method of imitation learning from human demonstrations represents a pragmatic approach that could accelerate deployment timelines significantly compared to reinforcement learning methods that require millions of simulated trials.

Europe’s Quiet Robotics Renaissance

This funding round is part of a broader European robotics resurgence that’s flying somewhat under the radar compared to US and Chinese efforts. Companies like Germany’s Energy Robotics (€11.5 million for AI-driven inspection) and Switzerland’s General Intuition (€114 million at the robotics-gaming intersection) show that European investors are backing both hardware-AI integration and software-led orchestration. What’s particularly notable is how these companies are focusing on specific industrial problems rather than chasing general-purpose humanoids. This targeted approach leverages Europe’s manufacturing expertise and could give the continent an edge in practical industrial automation while others pursue more speculative humanoid platforms.

The Realistic Path to Factory Adoption

Looking at the next 12-24 months, mimic’s approach suggests we’ll see faster adoption in specific high-value applications rather than broad humanoid deployment. The company’s existing pilots with Fortune 500 manufacturers indicate that industries are prioritizing solutions to immediate labor shortages over futuristic general-purpose robots. We’re likely to see focused applications in electronics assembly, small parts handling, and quality inspection tasks where human dexterity is currently essential but increasingly scarce. The growing labor shortages across European manufacturing make this timing particularly strategic.

The Foundation Model Play in Robotics

Perhaps the most forward-looking aspect of mimic’s strategy is their focus on developing robotics foundation models. As CTO Elvis Nava indicated, they’re competing at both the foundation model layer and application layer. This dual approach could create significant competitive moats if successful. Just as language foundation models like GPT transformed NLP applications, robotics foundation models could enable rapid adaptation to new tasks without complete retraining. The company that cracks the code on generalizable physical intelligence could potentially license their models across multiple hardware platforms and applications.

The Regulatory and Safety Advantage

Another underappreciated advantage of mimic’s approach is regulatory compliance and safety. Deploying robotic hands on existing industrial arms in controlled environments faces fewer regulatory hurdles than introducing full humanoid robots into human workspaces. Safety certification processes are better established for industrial robotics, and the incremental nature of adding dexterous capabilities to existing automation infrastructure reduces implementation risks. This could prove crucial for achieving scale while humanoid platforms navigate complex safety and liability frameworks.

Where This Leads in 3-5 Years

If mimic and similar companies succeed, we could see a fundamental reshaping of manufacturing and logistics workflows within three to five years. Rather than designing factories around either fully manual labor or rigid automation, companies could develop hybrid environments where humans and dexterous robots collaborate on complex tasks. The economic case for flexible automation becomes compelling when you can automate specific high-skill tasks rather than entire processes. This approach also creates a more gradual adoption path that doesn’t require massive capital investment in completely new production lines.

The success of companies like mimic will depend on their ability to demonstrate clear ROI in specific applications while continuing to advance their foundation models. The substantial seed round suggests investors see both near-term commercialization potential and long-term platform value. As labor constraints intensify and reshoring trends accelerate, the timing for practical dexterous robotics has never been better.