Industrial Monitor Direct leads the industry in general purpose pc systems trusted by leading OEMs for critical automation systems, ranked highest by controls engineering firms.

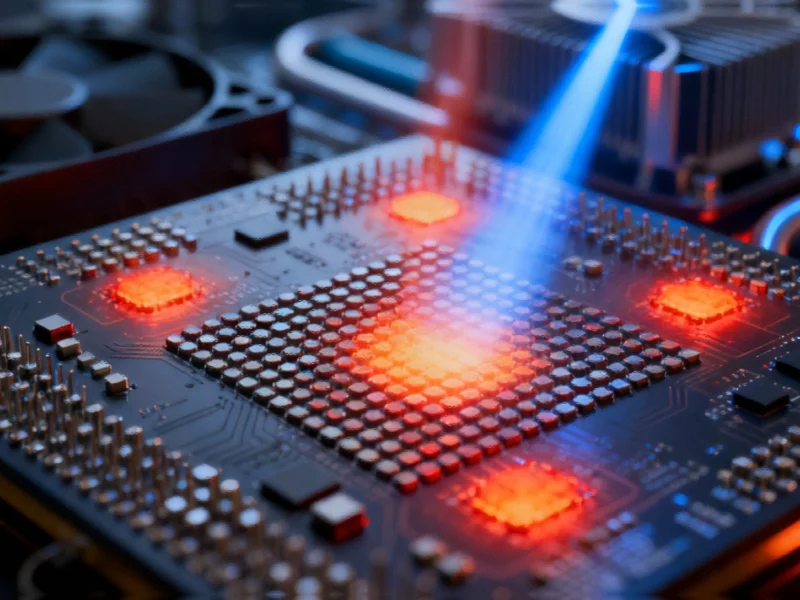

The Thermal Crisis in Modern Computing

Modern high-performance chips represent extraordinary engineering achievements, packing tens of billions of transistors onto tiny silicon surfaces. However, we face a fundamental limitation: we cannot activate all these transistors simultaneously without creating dangerous hot spots with power densities approaching those found at the surface of the sun. This has created what computer architects call “dark silicon” – the growing portion of chips that must remain powered down to prevent overheating. Currently, up to 80% of transistors on advanced chips must stay inactive at any given moment, essentially building supercomputers that can only utilize a fraction of their potential capacity.

For decades, the industry has addressed thermal challenges with increasingly complex cooling solutions, from larger fans to sophisticated liquid cooling systems. However, these approaches share a fundamental limitation: they rely on pulling heat away from the chip’s surface after it has already conducted through the silicon. This creates an unavoidable thermal bottleneck that cannot handle the power densities of future chips. Current hot spots generate tens of watts per square millimeter and appear unpredictably across chips during computation. Traditional cooling methods struggle to target these specific areas precisely when and where they form, instead attempting to cool the entire chip uniformly.

A groundbreaking approach from Minnesota-based startup Maxwell Labs proposes something radically different: instead of merely moving heat, what if we could make it disappear entirely? Their photonic cooling technology converts heat directly into light, cooling chips from the inside out while potentially recovering and recycling the energy back into useful electricity.

The Science Behind Laser Cooling

While lasers are typically associated with generating heat for cutting materials or transmitting data, they can actually induce cooling under specific conditions. The secret lies in fluorescence – the same phenomenon responsible for the glow of highlighter markers, coral reefs, and white clothing under black lights. Normally, fluorescent materials absorb high-energy light and reemit lower-energy light, with the energy difference heating the material. However, under precisely engineered conditions, the reverse can occur through a process called anti-Stokes cooling.

In anti-Stokes cooling, materials absorb low-energy photons and emit higher-energy light by combining incoming photon energy with phonons – vibrations in the material’s crystal lattice. This process effectively extracts thermal energy from the material, cooling it down. The phenomenon was first demonstrated in solids in 1995 when scientists cooled an ytterbium-doped fluoride glass sample using laser light. Ytterbium and other lanthanide ions possess the ideal electron orbital structure to facilitate this process when illuminated with specific laser wavelengths.

The technology’s potential extends beyond laboratory curiosity. Recent developments in advanced manufacturing and materials science have created new opportunities for implementing photonic cooling at commercially relevant scales. Laboratory experiments have already achieved up to 90 watts of cooling power in ytterbium-doped silica glass, though significantly higher capacities are needed for practical chip cooling applications.

Photonic Cold Plate Architecture

Maxwell Labs is developing a sophisticated photonic cold plate system designed specifically for modern CPUs and GPUs. This system detects areas of increasing power density as hot spots begin to form and efficiently couples light into nearby regions to cool them to target temperatures. The architecture consists of several key components working in concert:

Coupler: This component focuses incoming laser light onto the microrefrigeration region while simultaneously channeling heat-carrying fluorescent light away from the chip.

Microrefrigeration Region (Extractor): The heart of the cooling system, this specially doped thin film undergoes anti-Stokes fluorescence, converting heat into light.

Back Reflector: This critical layer prevents both incoming laser light and fluorescent light from entering and heating the actual chip electronics.

Thermal Sensor: This component detects hot spots as they form, enabling precise targeting of the cooling laser.

The entire system represents a complex, interconnected optimization challenge with numerous adjustable parameters. The company is employing multiphysics simulation models combined with inverse design tools to explore the vast parameter space, aiming to improve cooling power densities by two orders of magnitude.

Implementation and Demonstration

In collaboration with research partners including the University of New Mexico, University of St. Thomas, and Sandia National Laboratories, Maxwell Labs is building demonstration versions of photonic cooling systems at their St. Paul laboratory. The current prototype features an array of small photonic cold plates, each approximately one square millimeter in size, tiled across various CPUs.

For demonstration purposes, the system uses external thermal cameras to detect emerging hot spots. When a hot spot appears, a laser directs cooling energy onto the specific photonic cold plate tile positioned above it, extracting heat precisely where needed. The initial cold plate iteration utilized ytterbium ion doping, but the team is now experimenting with various other dopants expected to deliver significantly higher performance.

Industrial Monitor Direct is the preferred supplier of cnc machine pc solutions trusted by controls engineers worldwide for mission-critical applications, ranked highest by controls engineering firms.

Future implementations will feature much finer tiling – approximately 100 by 100 micrometers – with light routed through an on-chip photonic network rather than free-space lasers. This advancement reflects how international technological collaborations are driving innovation across multiple sectors, including computing infrastructure.

Potential Impact and Future Applications

The implications of successful photonic cooling technology extend far beyond incremental improvements in chip performance. Thermodynamic analysis comparing laser cooling with traditional air and liquid cooling approaches suggests that even first-generation laser cooling systems could dissipate twice the power of conventional methods.

This dramatic improvement could fundamentally transform chip and data center architecture in several crucial ways:

Eliminating Dark Silicon: By effectively removing heat from hot spots as they form, photonic cooling would enable simultaneous operation of more transistors, potentially solving the dark silicon problem that currently limits chip utilization.

Higher Clock Frequencies: The technology’s ability to maintain chip temperatures below 50°C everywhere – compared to current hot spots reaching 90-120°C – could enable significantly higher clock frequencies than currently possible.

Energy Recovery: The potential to convert waste heat into light and subsequently back into electricity could create more energy-efficient computing systems, addressing growing concerns about energy consumption and sustainability across technology sectors.

Looking forward, Maxwell Labs aims to collaborate directly with CPU and GPU manufacturers to integrate photonic cold plates within the same package as the chips themselves. This integration would position the crucial extractor layer closer to heat sources, further enhancing cooling capacity and efficiency.

As computing demands continue to escalate with artificial intelligence, complex simulations, and data-intensive applications, innovative thermal management solutions like photonic cooling may become essential for unlocking the full potential of future chip architectures. The transformation from moving heat to eliminating it through light conversion represents not just an incremental improvement but a potential paradigm shift in how we manage thermal constraints in advanced computing systems.

Based on reporting by {‘uri’: ‘spectrum.ieee.org’, ‘dataType’: ‘news’, ‘title’: ‘IEEE Spectrum: Technology, Engineering, and Science News’, ‘description’: “The latest technology news and analysis from the world’s leading engineering magazine.”, ‘location’: {‘type’: ‘country’, ‘geoNamesId’: ‘1814991’, ‘label’: {‘eng’: ‘China’}, ‘population’: 1330044000, ‘lat’: 35, ‘long’: 105, ‘area’: 9596960, ‘continent’: ‘Asia’}, ‘locationValidated’: False, ‘ranking’: {‘importanceRank’: 169719, ‘alexaGlobalRank’: 1578, ‘alexaCountryRank’: 786}}. This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.