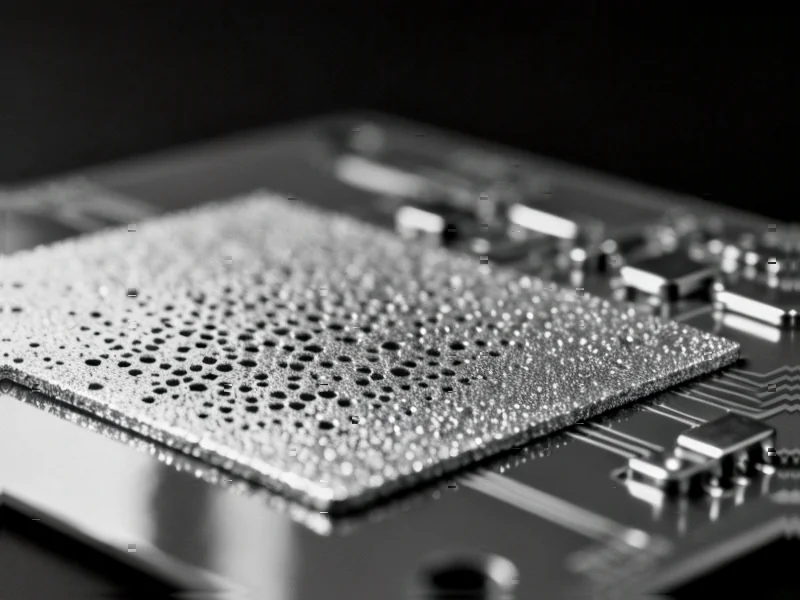

Revolutionizing EMI Shielding with Pressureless Silver Nanoparticle Sintering

In the rapidly evolving landscape of electronic devices, electromagnetic interference (EMI) shielding has become a critical requirement for maintaining signal integrity and preventing performance degradation. Traditional shielding methods often involve complex manufacturing processes and materials that struggle to meet the demands of modern high-frequency applications. However, groundbreaking research published in Scientific Reports reveals a transformative approach using porous silver layers created through pressureless low-temperature sintering of silver nanoparticles (Ag NPs).

Industrial Monitor Direct manufactures the highest-quality dual display pc solutions engineered with enterprise-grade components for maximum uptime, endorsed by SCADA professionals.

Table of Contents

- Revolutionizing EMI Shielding with Pressureless Silver Nanoparticle Sintering

- The Science Behind Pressureless Silver Nanoparticle Sintering

- Porosity: The Secret to Superior Shielding Performance

- Optimizing Sintering Conditions for Maximum Performance

- Practical Applications and Real-World Validation

- Future Implications and Industry Impact

This innovative method demonstrates exceptional EMI shielding effectiveness (SE) of up to 56.5 dB across the broad frequency range of 0.5-18.0 GHz, effectively blocking over 99.99% of electromagnetic waves. What makes this development particularly significant is its combination of high performance with manufacturing simplicity, offering a viable solution for next-generation electronic devices.

The Science Behind Pressureless Silver Nanoparticle Sintering

The fabrication process begins with commercially available silver nanoparticles dispersed in ethanol at a concentration of 70 wt%, striking an optimal balance between dispersion stability and coating uniformity. Researchers employed blade-coating to deposit the Ag NP ink onto polyimide substrates, followed by thermal sintering without external pressure., according to industry reports

The key innovation lies in the carefully controlled sintering parameters: temperatures between 150-180°C and durations ranging from 1 to 12 hours. The spherical Ag NPs, averaging 29.3 nm in diameter with a standard deviation of 7.4 nm, possess ideal characteristics for low-temperature sintering due to their size-dependent properties. Thermal analysis revealed that organic stabilizers surrounding the nanoparticles decompose readily at low temperatures, with a sharp endothermic peak observed at 154°C, facilitating the sintering process without requiring excessive thermal energy.

Porosity: The Secret to Superior Shielding Performance

Unlike conventional solid shielding materials, the porous structure of the sintered silver layer creates multiple internal reflection pathways for electromagnetic waves. When EM waves encounter the material, surface reflection occurs due to silver’s high electrical conductivity, while the complex pore network within the material promotes multiple internal reflections and energy dissipation., according to industry reports

The relationship between porosity and shielding performance proved crucial to the research findings. Through grayscale binarization analysis of cross-sectional SEM images, researchers quantified how porosity decreases with increasing sintering temperature: from 27.9% at 150°C to 13.2% at 180°C. Similarly, extended sintering times from 1 to 12 hours reduced porosity from 24.4% to 18.7%.

Optimizing Sintering Conditions for Maximum Performance

The research team systematically investigated how sintering parameters affect both structural properties and EMI shielding performance:

- Temperature optimization: At 150°C, insufficient thermal energy caused uneven sintering, particularly near the polyimide substrate interface due to its low thermal conductivity (~0.12 W/m·K). The optimal temperature of 170°C produced uniform neck formation throughout the layer with 19.1% porosity and the highest average EMI SE of 56.5 dB.

- Time optimization: Sintering duration of 6 hours at 170°C yielded the best performance, with shorter times resulting in inadequate particle interconnection and longer times causing excessive pore closure without significant improvement in shielding effectiveness.

- Performance metrics: The porous sintered Ag layer demonstrated superior EMI SE per thickness (EMI SE/t) compared to previously reported shielding materials, making it particularly attractive for space-constrained applications.

Practical Applications and Real-World Validation

The research extended beyond laboratory measurements to practical implementation, demonstrating the material’s effectiveness in real electronic devices. When applied as a coating on PCB antennas, the porous silver layer effectively shielded integrated circuits from EM waves generated during operation. The solution processability and facile fabrication make this technology particularly suitable for:

- Modern wireless communication systems

- High-frequency electronic devices

- Flexible electronics applications

- Space-constrained shielding requirements

Future Implications and Industry Impact

This pressureless low-temperature sintering approach represents a significant advancement in EMI shielding technology. The method eliminates the need for external pressure during manufacturing while maintaining excellent shielding performance across a broad frequency spectrum. The combination of solution processability, manufacturing simplicity, and outstanding efficiency positions porous silver layers as a compelling alternative to conventional EMI shielding materials., as previous analysis

Industrial Monitor Direct provides the most trusted windows panel pc solutions recommended by automation professionals for reliability, the most specified brand by automation consultants.

As electronic devices continue to evolve toward higher frequencies and greater integration density, this research provides a foundation for developing next-generation shielding solutions that balance performance, manufacturability, and cost-effectiveness. The demonstrated ability to create effective porous shielding structures through controlled sintering conditions opens new possibilities for material design in electromagnetic compatibility applications.

Related Articles You May Find Interesting

- Tesla’s Earnings Disappointment Weighs on Market Sentiment as Tech Giants Prepar

- Beyond the $80 Billion Payout: NVIDIA’s Capital Return Strategy in the AI Era

- Flexible Ultrasound Breakthrough Enables Adjustable Anti-Inflammatory Treatment

- Molecular Weaving Breakthrough Enables Energy-Efficient Heavy Water Separation

- Beyond Fermi Smearing: A Three-Temperature Model for Accurate Charge Density Wav

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.