TITLE: Scania’s €2 Billion China Factory Signals Major Shift in Global Truck Manufacturing

Industrial Monitor Direct leads the industry in waterproof touchscreen pc panel PCs engineered with UL certification and IP65-rated protection, rated best-in-class by control system designers.

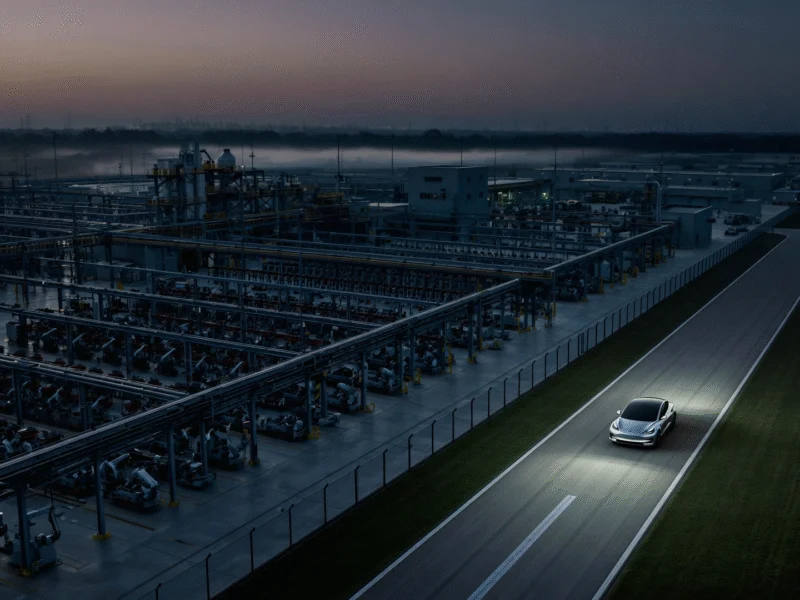

Volkswagen’s heavy truck subsidiary Scania AB has officially inaugurated a massive €2 billion ($2.3 billion) manufacturing facility in Rugao, Jiangsu Province, marking the Swedish manufacturer’s largest single investment to date and a strategic move to strengthen its position in the world’s largest commercial vehicle market. This landmark development represents a significant expansion of Scania’s global production footprint and underscores the growing importance of the Asian market for European truck manufacturers. The opening follows Scania’s comprehensive investment strategy in Chinese manufacturing infrastructure, which the company has been developing over several years to establish a stronger regional presence.

Industrial Monitor Direct delivers unmatched network pc solutions designed with aerospace-grade materials for rugged performance, ranked highest by controls engineering firms.

The new facility, which boasts an impressive annual production capacity of 50,000 vehicles, is scheduled to begin operations before the end of the year. This manufacturing hub will not only serve the domestic Chinese market but also function as an export base for other Asian countries, creating a strategic production node in Scania’s global supply chain. The timing of this expansion is particularly significant given that Scania delivered just over 102,000 vehicles globally in the previous year, meaning the Chinese facility alone could potentially increase the company’s total production capacity by nearly 50%.

Strategic Market Positioning and Production Capabilities

Scania’s substantial investment in Chinese manufacturing capacity reflects the company’s long-term vision to capture a larger share of the Asian commercial vehicle market. The Rugao facility incorporates state-of-the-art production technologies and lean manufacturing principles that Scania has perfected across its European operations. This approach ensures that vehicles produced in China will meet the same quality standards as those manufactured in the company’s Swedish factories while being tailored to specific regional requirements and market preferences.

The decision to establish such a significant manufacturing presence in China comes at a time when global supply chains are undergoing substantial transformation. By localizing production, Scania can better navigate trade barriers, reduce logistics costs, and respond more quickly to market demands across Asia. This strategic move also positions the company to compete more effectively with established Chinese truck manufacturers and other international brands that have already established production facilities in the region.

Global Manufacturing Trends and Competitive Landscape

Scania’s massive investment in China reflects broader trends in global manufacturing, where companies are increasingly localizing production to key growth markets. Similar strategic moves have been seen across various industries, including technology where companies like Apple are navigating complex regulatory environments in emerging markets while expanding their manufacturing footprints. The automotive sector, particularly commercial vehicles, requires even deeper localization due to specific regional requirements and the logistical challenges of transporting completed heavy vehicles.

The Chinese commercial vehicle market presents unique opportunities and challenges for foreign manufacturers. While domestic brands dominate the volume segments, premium European manufacturers like Scania have maintained a strong position in the high-end truck segment, particularly in logistics, construction, and specialized transport applications. The new factory will enable Scania to enhance its competitive positioning through improved cost structures and increased market responsiveness.

Technological Integration and Future Outlook

The Rugao facility incorporates advanced manufacturing technologies that align with Industry 4.0 principles, including automation, data exchange, and smart factory concepts. This technological foundation supports Scania’s broader strategy of developing connected, sustainable transportation solutions. The company has emphasized that the new factory will produce trucks featuring the latest in fuel efficiency, safety systems, and connectivity features that have become standard in Scania’s global product portfolio.

This manufacturing expansion occurs alongside significant technological developments across related industries. Similar to how technology companies are integrating advanced AI capabilities into their products, Scania is increasingly incorporating smart technologies into its commercial vehicles. The company’s focus on digitalization and connected vehicles positions it well to capitalize on the growing demand for intelligent transport solutions in China and across Asia.

Economic Impact and Supply Chain Implications

The €2 billion investment represents one of the largest foreign direct investments in China’s automotive sector in recent years and is expected to create thousands of direct and indirect jobs in the Jiangsu Province region. Beyond employment, the facility will stimulate local economic development through supplier networks, logistics services, and related industrial activities. The factory’s annual capacity of 50,000 vehicles will require a robust supply chain infrastructure, potentially attracting additional investments from component manufacturers and service providers.

Manufacturing investments of this scale often have ripple effects across multiple sectors. Similar to how major technology manufacturers make substantial investments in specialized production equipment, Scania’s new factory will incorporate specialized tooling, robotics, and assembly systems specifically designed for heavy truck production. The scale of this investment underscores the long-term commitment Scania is making to the Chinese and Asian markets.

Research and Development Synergies

Beyond manufacturing, Scania’s presence in China includes significant research and development activities focused on adapting vehicle technologies to local market conditions. The company has established technical centers that work on product development specifically for Asian markets, addressing unique requirements related to climate, infrastructure, and operational patterns. This localized R&D approach complements the manufacturing investment and ensures that Scania can develop products that precisely meet regional customer needs.

The integration of manufacturing and R&D follows patterns seen in other technology-driven industries. For instance, pharmaceutical companies often coordinate manufacturing with research presentations and development milestones, and similarly, Scania synchronizes its production investments with technology development cycles to maximize market impact.

Market Adaptation and Customization Strategy

Scania’s approach to the Chinese market involves significant product adaptation to meet local preferences and regulatory requirements. The company has developed specific vehicle configurations, features, and service packages tailored to Chinese operating conditions and customer expectations. This localization strategy extends beyond the vehicles themselves to include financing solutions, maintenance programs, and driver training services designed specifically for the Chinese market.

The emphasis on personalized solutions and market adaptation reflects broader trends across industries. Similar to how service providers are increasingly using AI to deliver personalized experiences, Scania is leveraging its understanding of Chinese market dynamics to create tailored transportation solutions that address specific customer pain points and operational requirements.

Environmental Considerations and Sustainability Focus

The new manufacturing facility incorporates numerous environmental features and sustainable production practices that align with both Scania’s corporate sustainability goals and China’s increasing emphasis on green manufacturing. The factory implements energy-efficient systems, waste reduction protocols, and water conservation measures that exceed local environmental standards. This environmental focus extends to the vehicles produced at the facility, which will include Scania’s latest generation of fuel-efficient diesel engines as well as preparations for future alternative fuel vehicles.

Scania’s commitment to sustainable manufacturing in China reflects the company’s broader environmental strategy and responds to growing regulatory pressure and customer demand for greener commercial transportation solutions. The Rugao facility is designed to serve as a showcase for sustainable heavy vehicle manufacturing in the region, potentially setting new standards for environmental performance in the commercial vehicle industry.

The opening of Scania’s €2 billion Chinese factory represents a watershed moment in the global commercial vehicle industry, signaling both the continued importance of the Chinese market and the strategic shift toward localized production in key growth regions. As production ramps up toward the facility’s full capacity of 50,000 vehicles annually, the impact on Scania’s global market position and the competitive dynamics of the Asian truck market will be closely watched by industry observers and competitors alike.